MES

Manufacturing Execution System

The NMES tracking platform involves several application blocks communicating with each other through cloud computing.

The most significant application blocks are:

- The backendThe most significant application blocks are:

- The frontend

- The API REST

- The initialization devices (RIFD or traditional thermal/multifunction printers, markers, etc.)

- The reading devices (Barcode readers, RFID devices, etc.)

The goal is to ensure product traceability, speed up and reduce the error of the operator who is going to work on a given product following a predefined path.

To achieve this goal, the use of various initialization and reading devices is planned. These devices, by communicating with the system, will facilitate the operator during the work activity, helping him to exchange data more easily with the technical department during the various stages.

To achieve this goal, the use of various initialization and reading devices is planned. These devices, by communicating with the system, will facilitate the operator during the work activity, helping him to exchange data more easily with the technical department during the various stages.

Digitizing infrastructure

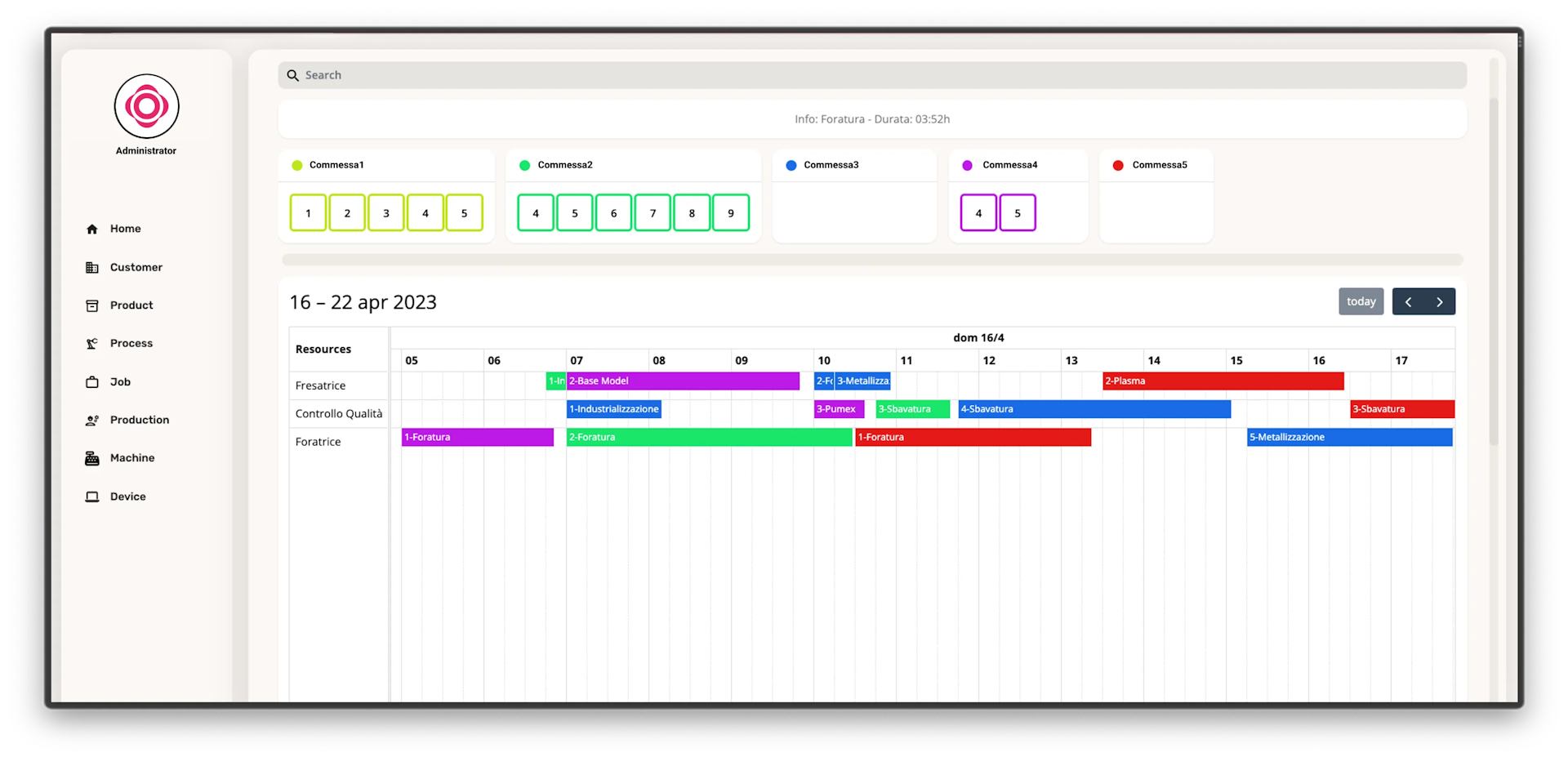

The introduction of RFID technology will enable the customer to digitize job orders and have a more accurate and computerized data of them, ensuring automated progress of work phases.Monitor production

The system will allow monitoring of production so you can see which process steps take the most time and where you can optimize work activity.Traceability

The system will allow traceability of work orders and parts produced through the use of traditional or RFID technology.